Not to be seen on pictures, but important: It's a good idea to take the two elevator-mainspars E402, drill and cleco E403 and 404 to them, hold the assembly to the finished stabilizer and put the rudder-arm close and parallel to the outer end of the stabilizer, that distance is not mentioned in the plans, but 4-5 mm will be ok. In this position trace the location of the rod-end bearings and mark the Wd 405 control-horn. This way you will be on the save side and your assembly will fit. Now lay both spars on a flat surface, Wd 405's back to back and clamp the two E402's the way the centerline calls for. Do they run up parallel? Fine, go ahead. I realised, that the welded control-horns were slightly misaligned and if I would have done it exactly by plans all the way, my Wd405's would be misaligned at parallel elevators. But in this stage you can align the assembly before you drill the E402's. It sounds complicated, but it works, my elevators are straight and the control-horns meet 100% back to back ;o) Keep in mind what the plans call for: Never build the elevators or the trim-tab strictly from the plans, they have to fit your stabilizer and elevator. In fact, I have'nd looked to the plans one single time while building the trim tab. You know how it's got to look, so trace it from your construction and use the plans as a rough guide this time. By the way, forget about the horror-stories about the trim-tab-construction. With patience you will win. I wonder why there are less stories about fiberglass, haha... |

|

Now I held

it to the stabilizer, located the rod-end bearings,

drilled them and bolted it on. So I was shure to meet

both ends exactly, the Wd 405 and on the other side the

E404/403 assembly. Now I held

it to the stabilizer, located the rod-end bearings,

drilled them and bolted it on. So I was shure to meet

both ends exactly, the Wd 405 and on the other side the

E404/403 assembly. |

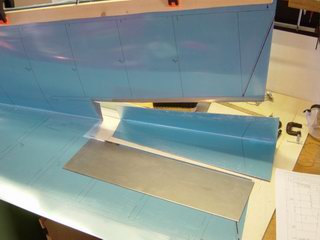

To hold

the outer angle permanently, just glue in an angle with

hot-melt-adhesive, you can take the assembly, carry it

over to the skin and trace the lines. The angle will be

removed after that, of course... To hold

the outer angle permanently, just glue in an angle with

hot-melt-adhesive, you can take the assembly, carry it

over to the skin and trace the lines. The angle will be

removed after that, of course... |

So,

nothing can happen, it will fit! Spars and stabilizer

match perfectly, so it's time to cut. I'm away from

cutting by hand, it allways left some shear-marks. The

little Dremel cut-off discs in a high-rpm airtool work

great. If you don't like your dentist, choose another

way, same sound ;o)) Wear eye-protection, these thin

discs are like shrapnels! So,

nothing can happen, it will fit! Spars and stabilizer

match perfectly, so it's time to cut. I'm away from

cutting by hand, it allways left some shear-marks. The

little Dremel cut-off discs in a high-rpm airtool work

great. If you don't like your dentist, choose another

way, same sound ;o)) Wear eye-protection, these thin

discs are like shrapnels! |

Cutting

out the trim-tab. Cutting

out the trim-tab. |

Reenforcement-rib

for the trim-cable support. Reenforcement-rib

for the trim-cable support. |

It really

gets floppy when the trim-tab is gone.... It really

gets floppy when the trim-tab is gone.... |

.....but

it disappears after this! .....but

it disappears after this! |

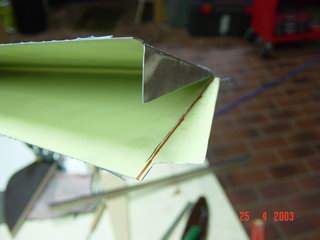

The most

nerve-wracking mission: Bent the edges. I fabricated a

small piece of hardwood that fits inside the elevator and

put the scrap form the jig on top. After clamping you can

bend and hammer it in place, but never hit the aluminum

directly, use a small piece of wood in between. Oh, and

one think you will not find in the plans: Do the dimples

in the area where the E406 is riveted with pop-rivets

BEFORE you do the final bending of the skin, they are ot

of reach after that! The most

nerve-wracking mission: Bent the edges. I fabricated a

small piece of hardwood that fits inside the elevator and

put the scrap form the jig on top. After clamping you can

bend and hammer it in place, but never hit the aluminum

directly, use a small piece of wood in between. Oh, and

one think you will not find in the plans: Do the dimples

in the area where the E406 is riveted with pop-rivets

BEFORE you do the final bending of the skin, they are ot

of reach after that! |

The

result. The

result. |

Now you

can fit E412 to the elevator-arm. You can subsitute the

pop-rivets with solid AN rivets, if you rivet the

elevator-arm skin to the elevator skin before you slide

the hole spar-assembly into it. No a must-do, but it's

nice to substitute pop-rivets, is'nt it? Now you

can fit E412 to the elevator-arm. You can subsitute the

pop-rivets with solid AN rivets, if you rivet the

elevator-arm skin to the elevator skin before you slide

the hole spar-assembly into it. No a must-do, but it's

nice to substitute pop-rivets, is'nt it? |

...clecoed. ...clecoed. |

That

water-pipe torchure again! That

water-pipe torchure again! |

Puh! Puh! |

Riveted

leading-edge. Riveted

leading-edge. |

At first I

built the trim-tab from light cardboard, fitted it to the

elevator and traced it to the skin. Now it's once again

time to bent the edges. At first I

built the trim-tab from light cardboard, fitted it to the

elevator and traced it to the skin. Now it's once again

time to bent the edges. |

...it

looks as if I did it in 10 minutes. It looks.....but it

took a lot of time. I have tried everything not get in

that row and call Vans for another trim-tab ;o) (OK, I

had to order two E402's, bad enough..) ...it

looks as if I did it in 10 minutes. It looks.....but it

took a lot of time. I have tried everything not get in

that row and call Vans for another trim-tab ;o) (OK, I

had to order two E402's, bad enough..) |

Now you

can rivet the trim-tab-spar in place. Now you

can rivet the trim-tab-spar in place. |

This

improvement is taken from an old issue of the RVator,

some RV's developed cracks in the skin just on top of the

trim-cable angle. This additional anglebracket should

help to aviod it. This

improvement is taken from an old issue of the RVator,

some RV's developed cracks in the skin just on top of the

trim-cable angle. This additional anglebracket should

help to aviod it. |

Now the

piano-hinge is riveted to the left elevator. Now the

piano-hinge is riveted to the left elevator. |

Tadaa! It

aligns ;o) Tadaa! It

aligns ;o) |

This is

the way I choose to secure the hingepin. It is long

enough to bend it 90 degrees, so I fabricated a small

angle from scrap and shaped it, so the outer end is 2-3

mm away from the spar and notched at the top. The pin is

save from working out and you can release him without any

tools. This is

the way I choose to secure the hingepin. It is long

enough to bend it 90 degrees, so I fabricated a small

angle from scrap and shaped it, so the outer end is 2-3

mm away from the spar and notched at the top. The pin is

save from working out and you can release him without any

tools. |

This is

how it looks. There are some other suggestions about this

problem, but they all have to do with bolts or wire. This

one is for free, it takes 10 minutes to build and looks

clean. And why not use the additional rivets in the kit? This is

how it looks. There are some other suggestions about this

problem, but they all have to do with bolts or wire. This

one is for free, it takes 10 minutes to build and looks

clean. And why not use the additional rivets in the kit?Now, time for fiberglass. Have I mentioned that I hate fiberglass? I insulated my house with that stuff, and from that day on it's a no-no for me. And the tips do not fit very good..... |