![]()

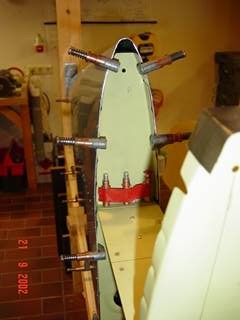

27.08.2002 START! The main spar of the horizontal stabilizer. 2 profiles drilled to the spar. You drill into the jig and cleco as you go. |

|

After

priming and riveting. I use Zincchromate from PPG DeSoto,

used at Airbus Industies as well. It's not easy to get,

see the download area for the data-sheet and sources to

buy it. To get some Marihuana is more simple. This is

bullet-proof stuff, but you get cancer for free, if you

are mad enough to spray without clean air supply. That's

the reason, why buying it is so hard. (BTW, to buy dope

is easier AND less expesive, I think. As they've called

up the price, I got a little depressive...) After

priming and riveting. I use Zincchromate from PPG DeSoto,

used at Airbus Industies as well. It's not easy to get,

see the download area for the data-sheet and sources to

buy it. To get some Marihuana is more simple. This is

bullet-proof stuff, but you get cancer for free, if you

are mad enough to spray without clean air supply. That's

the reason, why buying it is so hard. (BTW, to buy dope

is easier AND less expesive, I think. As they've called

up the price, I got a little depressive...) |

Now you

have to measure up all ribs, place and drill them. The

skin is simulated by little strips of scatch. The spar is

locked to the jig for a leveled alignment. Now you

have to measure up all ribs, place and drill them. The

skin is simulated by little strips of scatch. The spar is

locked to the jig for a leveled alignment. |

Skeleton

all done, time to fit the skin. Skeleton

all done, time to fit the skin. |

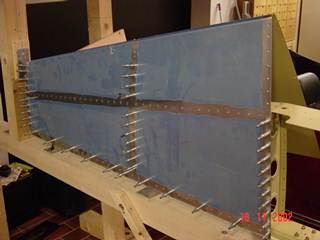

Here I

don't followed the manual. They suggest to drill through

the skin directly into the skeleton. Then chance of

misalignment was to great for me, so I did it in a

different way. I clamped one side, peeled back the

opposite one and marked the position of the ribs with a

sharpie. The same procedure on the other side, then I

took off the skin, made the layout of the rivet-lines on

the inside of the skin, predrilled the holes from that

side, clamped it back on the skeleton and drilled with

the correct size. No chance of missing a rib and

beautiful rivet-lines! Here I

don't followed the manual. They suggest to drill through

the skin directly into the skeleton. Then chance of

misalignment was to great for me, so I did it in a

different way. I clamped one side, peeled back the

opposite one and marked the position of the ribs with a

sharpie. The same procedure on the other side, then I

took off the skin, made the layout of the rivet-lines on

the inside of the skin, predrilled the holes from that

side, clamped it back on the skeleton and drilled with

the correct size. No chance of missing a rib and

beautiful rivet-lines! |

Hellraiser?? Hellraiser??No, the drilled skin, clecoed to the skeleton. |

This is

how it looks from the inside. The upper (front) side ist

clecoed, the other side is peeled back for taking the

picture. This is

how it looks from the inside. The upper (front) side ist

clecoed, the other side is peeled back for taking the

picture. |

The

ready-drilled skin must be dimpled with the C-frame-tool. The

ready-drilled skin must be dimpled with the C-frame-tool. |

This is

how it looks after dimpling. This is

how it looks after dimpling. |

Cleco it a

last time..... Cleco it a

last time..... |

Vernieten!

(Die Daten auf den Fotos stimmen. Ich habe die Haut erst

aufgenietet, nachdem Wilhelm Tank, mein (sehr netter,

RV6-bauender!) Blechprüfer, alles gesehen hat. In der

Zwischenzeit habe ich das Seitenleitwerk bis zum selben

Stadium gebaut)...and rivet. I had to make a break,

because the offical inspector (Wilhelm Tank, a very nice

guy and builder of a RV6) had to take a look inside. I

passed that inspection, so I started to close the

stabilizers. Vernieten!

(Die Daten auf den Fotos stimmen. Ich habe die Haut erst

aufgenietet, nachdem Wilhelm Tank, mein (sehr netter,

RV6-bauender!) Blechprüfer, alles gesehen hat. In der

Zwischenzeit habe ich das Seitenleitwerk bis zum selben

Stadium gebaut)...and rivet. I had to make a break,

because the offical inspector (Wilhelm Tank, a very nice

guy and builder of a RV6) had to take a look inside. I

passed that inspection, so I started to close the

stabilizers. |

One half

closed..... One half

closed..... |

....and

finally the horizontal stabilizer is done! The fiberglass

tibs will be installed together with all other fiberparts

at the end of this part of the project. ....and

finally the horizontal stabilizer is done! The fiberglass

tibs will be installed together with all other fiberparts

at the end of this part of the project. |