At first you have to pour lead into the tip ribs. I took more than needed, so the elevator is overbalanced, but the final paint will be mostly behind the turning point, so better drill some out than pour some in. |

|

Oops, a

little too much, so I had to file it off, but... Oops, a

little too much, so I had to file it off, but... |

...no need

to do any filling after this, no bondo here. ...no need

to do any filling after this, no bondo here. |

I glued in

some washers to avoid cracks from those pop-rivets. I

don't know if you have to do this, but it would be a pity

if it happens. I glued in

some washers to avoid cracks from those pop-rivets. I

don't know if you have to do this, but it would be a pity

if it happens. |

I riveted

and glued with epoxy resin at once. You can jig it and

there will be no waves on the surface. Esp. the main skin

is very thin and you have to rivet close to the edge. And

as another effect, there is no gap between skin and

fiberglass after sanding. I riveted

and glued with epoxy resin at once. You can jig it and

there will be no waves on the surface. Esp. the main skin

is very thin and you have to rivet close to the edge. And

as another effect, there is no gap between skin and

fiberglass after sanding. |

Clamp it

and turn off the light! Clamp it

and turn off the light! |

The rudder

foot was a little tricky, because you have to decide

where to cut it. It will not fit over the angle if you

only slot it. The plans say not much about it, so I

decided to cut of the leading edge. Now you can slide it

onto the rudder and there is no gap at the angle, but, of

course, a big gap at the leading edge... The rudder

foot was a little tricky, because you have to decide

where to cut it. It will not fit over the angle if you

only slot it. The plans say not much about it, so I

decided to cut of the leading edge. Now you can slide it

onto the rudder and there is no gap at the angle, but, of

course, a big gap at the leading edge... |

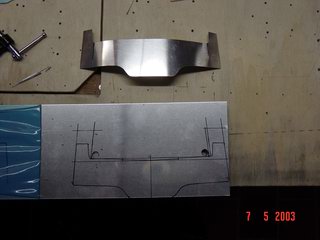

...so I

fabricated a little piece of aluminum, ...so I

fabricated a little piece of aluminum, |

rolled the

edge slightly with a slotted grip of a file, rolled the

edge slightly with a slotted grip of a file, |

...and

this is how it looks. ...and

this is how it looks. |

After

riveting it looks like a piece of the rudder-skin. It is

attached to the rudder main spar with two AN rivets on

each side, there is some place to do that. After

riveting it looks like a piece of the rudder-skin. It is

attached to the rudder main spar with two AN rivets on

each side, there is some place to do that. |

The

result. I sprayed all of the fiberglass to have a better

view for a smooth surface, you can detect it better this

way. The

result. I sprayed all of the fiberglass to have a better

view for a smooth surface, you can detect it better this

way. |

I have

installed a little Wheelen strobe as an ACL on top of the

vertical stabilizer, it is small, lightweight and

effective. Cut a hole into the fiberglass, wax the glass

of the ACL and laminate it into the fairing from the

inside. The glass is shaped to the outside on its foot,

so you will have a stop and it will not jump out. If you

have waxed enough, you can push the glass back to the

inside the next day. Now, wax again, reinsert it, do a

weird construction with waxed anything and fill in Epoxy,

mixed with microbaloons for weight-saving. I have

installed a little Wheelen strobe as an ACL on top of the

vertical stabilizer, it is small, lightweight and

effective. Cut a hole into the fiberglass, wax the glass

of the ACL and laminate it into the fairing from the

inside. The glass is shaped to the outside on its foot,

so you will have a stop and it will not jump out. If you

have waxed enough, you can push the glass back to the

inside the next day. Now, wax again, reinsert it, do a

weird construction with waxed anything and fill in Epoxy,

mixed with microbaloons for weight-saving. |

If the wax

works, I should be able to push the glass out

tomorrow.....should be.....wait and see :o( If the wax

works, I should be able to push the glass out

tomorrow.....should be.....wait and see :o( |

Waiting

for tomorrow. Waiting

for tomorrow. |

Strike!

OK, the shape needs some work ;o) Strike!

OK, the shape needs some work ;o) |

Step by

step.... Step by

step.... |

The

result. The first "Spirit of Gera"-touch,

grin.. The

result. The first "Spirit of Gera"-touch,

grin.. |

|

| READYREADYREADY! If I subtract holidays and

Christmas, I'm looking back on 6 months of work, some

sleepless nights, one major mistake with the E405's, a

lot of people I met, friendships we made and more than

400, maybe 500 hours of work. The RV-family is a great

supporter, thank you, it is a lot of fun on the way. Give me wings!!!!!!!

|