![]()

Here I'll show some more detailed pics, so you can oversee the whole process. This is for general use and to make yourself a picture of the necessary steps. Builders won't get new informations here, but many people (like me) use the Internet before the make the decision to start. |

|

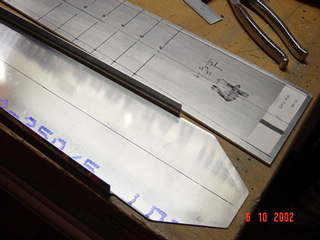

First

step: Draw a centerline, mark the rivet spacing and

predrill the holes. First

step: Draw a centerline, mark the rivet spacing and

predrill the holes. |

Then you

have to mark the cutting-lines and trim the doubler. Then you

have to mark the cutting-lines and trim the doubler. |

Now the

lower end is trimmed to the plans. Cutting discs and a

Dremel work great here. Offset snips would bent the

aluminum. Don't do that on 90degree bents! Now the

lower end is trimmed to the plans. Cutting discs and a

Dremel work great here. Offset snips would bent the

aluminum. Don't do that on 90degree bents! |

After

everything is marked and triple-checked, it's time to

drill. Straight into the working surface and clecoed

after each hole. This way there's no chance of

misalignment. After

everything is marked and triple-checked, it's time to

drill. Straight into the working surface and clecoed

after each hole. This way there's no chance of

misalignment. |

Now the

parts are aligned and trimmed to match. Now the

parts are aligned and trimmed to match. |

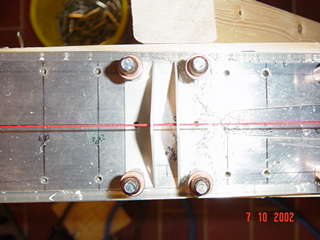

The

brackets are aligned by a tight drawn wire, so they match

to the centerline and to each other. The

brackets are aligned by a tight drawn wire, so they match

to the centerline and to each other. |

Disassambled

once more. Now you have to dimple the rivetholes, either

by dimpling with a squeezer or machining, if the

thickness of the skin will allow it. (See tool section) Disassambled

once more. Now you have to dimple the rivetholes, either

by dimpling with a squeezer or machining, if the

thickness of the skin will allow it. (See tool section) |

Now smooth

all flanges, file all edges to a round shape, treat the

surface with some Scotchbrite, clean with Aceton, prime

and spray with Zincchromate at last. I think is not a

good idea to go cheap at this point. You will never reach

these places after riveting. Corrosion-protection is a

must, esp. here in northern Germany. If you build and fly

in Mexico, maybe you will trust the ALCLAD. Now smooth

all flanges, file all edges to a round shape, treat the

surface with some Scotchbrite, clean with Aceton, prime

and spray with Zincchromate at last. I think is not a

good idea to go cheap at this point. You will never reach

these places after riveting. Corrosion-protection is a

must, esp. here in northern Germany. If you build and fly

in Mexico, maybe you will trust the ALCLAD.(Most parts of the RV's are plated with a thin layer of pure aluminum for corrosion-protection, but it is easily scratched when handling the parts during construction) |

After all:

Time to rivet! The C-frame tool works great here.... After all:

Time to rivet! The C-frame tool works great here.... |

...but

some rivets will bent, anyway. So, drill out very

carefully, replce, strike again, drill out once more and

strike. Another beer, drill out........and try to keep

cool. (Not that easy) ...but

some rivets will bent, anyway. So, drill out very

carefully, replce, strike again, drill out once more and

strike. Another beer, drill out........and try to keep

cool. (Not that easy) |

Done it! Done it! |

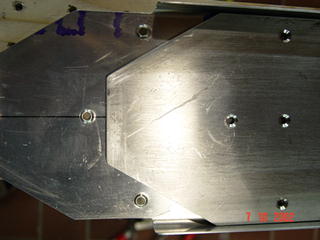

Here you

can see the AN426 countersunk head rivets in front. You

achieve a smooth surface. At this place the vertical

stabilizer will match to the fuselage later (much later,

grin) Here you

can see the AN426 countersunk head rivets in front. You

achieve a smooth surface. At this place the vertical

stabilizer will match to the fuselage later (much later,

grin) |

This foto

was taken in the 'pre-laser-aera', so strange

constructions were built to align the skeleton. There is

simply no straight, parallel line you can measure from,

so you have to be tricky. This foto

was taken in the 'pre-laser-aera', so strange

constructions were built to align the skeleton. There is

simply no straight, parallel line you can measure from,

so you have to be tricky. |

Skinning

is the same as done with the horizontal stabilizer. Skinning

is the same as done with the horizontal stabilizer. |

After

this, the parts are ripped apart once more, edges and

corners have to be smoothed, holes deburred and dimpled

and the surface has to be cleaned. Then prime and

protect. After

this, the parts are ripped apart once more, edges and

corners have to be smoothed, holes deburred and dimpled

and the surface has to be cleaned. Then prime and

protect.Before anything goes together forever, you have to assamble and disassamble parts ten times and more. |

Close shot

of the skeleton, ready to skin. Close shot

of the skeleton, ready to skin. |

Skinning

is a nerve-wracking job. You have to crawl on the floor

sometimes, your hand and the bucking-bar are trapped

inside the stabilizer, you are trying to imagine, if the

bar sits in the correct position to that rivet, the other

hand is holding the rivet gun, your eyes try to watch

around corners to align gun and surface, and then you

fire the gun. Puuh! If the bucking-bar slips off the

rivet or the gun is taken off too soon, you will produce

a half-moon-shaped mark on your new part. No need the

heat the shop here for me, I came out soaking wet with

one moon on the counter. Skinning

is a nerve-wracking job. You have to crawl on the floor

sometimes, your hand and the bucking-bar are trapped

inside the stabilizer, you are trying to imagine, if the

bar sits in the correct position to that rivet, the other

hand is holding the rivet gun, your eyes try to watch

around corners to align gun and surface, and then you

fire the gun. Puuh! If the bucking-bar slips off the

rivet or the gun is taken off too soon, you will produce

a half-moon-shaped mark on your new part. No need the

heat the shop here for me, I came out soaking wet with

one moon on the counter. |

At the

beginning you can peel back the skin and control the

rivets. The wire is a placeholder for the cable of the

beacon on top of the stabilizer. Once closed, you are in

trouble without it. At the

beginning you can peel back the skin and control the

rivets. The wire is a placeholder for the cable of the

beacon on top of the stabilizer. Once closed, you are in

trouble without it. |

Vertical

stabilizer all done! Vertical

stabilizer all done! |